ON-LINE

MANUAL

Pneumatic Requirements

Air Consumption

and Air Compressors

The air consumption,

especially the average air consumption, of a vibrator system is the

basis for calculating the size of the air compressor needed.

In the following

table the air consumption in liters per minute for 2 and 6 bar air operating

pressure are given. The values may vary about 10 % due manufacturing

tolerances.

Fig. 2.1. Air consumption

[liters per minute] of the Powtek vibrators

| Type |

30

PSI |

90 PSI |

* |

Type |

30 PSI |

90 PSI |

* |

Type |

30 PSI |

90 PSI |

| K-8 |

83 |

195 |

* |

R-50 |

100 |

195 |

* |

DAR-2 |

70 |

200 |

| K-10 |

92 |

200 |

* |

R-65 |

200 |

400 |

* |

DAR-3 |

100 |

300 |

| K-13 |

94 |

225 |

* |

R-80 |

290 |

570 |

* |

DAR-4 |

120 |

360 |

| K-16 |

122 |

280 |

* |

R-100 |

370 |

730 |

* |

DAR-5 |

130 |

390 |

| K-20 |

130 |

340 |

* |

R-120 |

500 |

970 |

* |

DAR-6 |

170 |

470 |

| K-25 |

160 |

425 |

* |

. |

. |

. |

* |

DAR-7 |

180 |

500 |

| K-30 |

215 |

570 |

* |

. |

. |

. |

* |

. |

. |

. |

| K-36 |

260 |

675 |

* |

. |

. |

. |

* |

. |

. |

. |

.

| Type |

30

PSI |

90 PSI |

* |

Type |

30

PSI |

90 PSI |

* |

Type |

30

PSI |

90 PSI |

| GT-4/6 |

33 |

83 |

* |

T-50-LP |

70 |

165 |

* |

FP-12-S |

1 |

25 |

| GT-8/10 |

46 |

112 |

* |

T-50-HP |

80 |

190 |

* |

FP-12-M |

1 |

20 |

| GT-13/16 |

120 |

390 |

* |

T-65-LP |

90 |

240 |

* |

FP-12-L |

1 |

20 |

| GT-20/25 |

185 |

455 |

* |

T-65-HP |

110 |

290 |

* |

FP-18-S |

5 |

57 |

| GT-30/36 |

330 |

745 |

* |

T-80-LP |

150 |

290 |

* |

FP-18-M |

4 |

25 |

| GT-40/48 |

425 |

970 |

* |

T-80-HP |

150 |

390 |

* |

FP-18-L |

5 |

46 |

| . |

. |

. |

* |

T-100-HP |

200 |

390 |

* |

FP-25-S |

13 |

93 |

| . |

. |

. |

. |

. |

. |

. |

. |

FP-25-M |

23 |

87 |

| . |

. |

. |

. |

. |

. |

. |

. |

FP-25-L |

18 |

93 |

| . |

. |

. |

. |

. |

. |

. |

. |

FP-35-S |

23 |

162 |

| . |

. |

. |

. |

. |

. |

. |

. |

FP-35-M |

24 |

141 |

| . |

. |

. |

. |

. |

. |

. |

. |

FP-35-L |

38 |

135 |

2.1.1. Calculation

of the average air consumption

FORMULAS |

1. Air Consumption according to table 2.1. : CONS. = ...... liters

/ minute |

|

2. Operating Factor (On/Off) x 100% : OPF = ...... % |

|

3. Average Air Consumption = CONS x OPF : ACON = ...... liters /

minute |

|

4. Total Average Consumption = ACON x NUMBER OF UNITS DRIVEN |

To get the average

consumption of several vibrators and/or other air consumers connected

to the same supply pipe, multiply the Average Air Consumption by the

number of units if the air consumption is the same. If the air comsumption

is not the same, do the calculation for every consumer separately and

add the results.

To determine the

size of the air compressor required it is recommended to add about 20

% as a safety figure to the above calculated demand since the values

given may vary. Also, leaks or additional installations may require

a larger compressor. Extra power for future installations may also be

necessary.

To define the air

compressor size required another figure is necessary. It is the highest

consumption at any given time. This figure can be estimated taking the

air consumption of all units that may be in operation at the same time

and the length of this period :

Highest Air Consumption

=Number of units x CONS for .... minutes

= ............

liters / minute during ....... minutes

Both the volume

of the highest air consumption as well as the average consumption of

the system should be used to determine the proper compressor.

Lubrication

Dry or not dry

? This is an important question. Generally speaking, lubrication always

increases the lifetime of moving parts since it significantly reduces

friction. But, lubricating ball vibrators is a waste of lubricants because

it will not visibly increase the vibrator’s lifetime whereas dry

running T-turbine ball bearings will fail quickly.

Thanks to special

material and treatments (teflon-coating, etc.) the operating friction

can be minimized so that piston vibrators (FP-series) and DAR-vibrators

alike have very good emergency running properties. Still, after time,

lubrication becomes necessary to avoid increased abrasion..

The question of

how many drops of oil per minute are sufficient or how many are too

much cannot be answered in general. It is possible that a reciprocating

or piston air compressor supplies sufficient oil in the air so that

the use of a lubricator is not necessary. Unfortunately, the same compressor

type may supply too much machinery oil if the leakage is too great which

causes the DAR-series to decrease in frequency and force due to oil

gumming. On the other hand, air compressors with built-in air dryers

require a line lubricator to keep T-turbine, DAR- and FP-vibrators from

wearing out quickly.

IMPORTANT: For lubrication

of Powtek vibrators use oil with the viscosity:

ISO VG 5 with 5cSt/40°C (5 centistokes or approx. 42.4 Susec or

5 cm2 sec2 )

The oil needs to

be non gumming. Some examples are listed below :

- Shell Tellus

Oil C5

- Esso Nuto H5

- Mobil Velocite

No.4

- BP Energol HP

5

- For food applications

: Mobil Whiterex 304 (vegetable base)

NOTE: Oil with

viscosity other than recommended will reduce frequency and power! For

FP-piston vibrators only, distilled water may be used instead of oil

with the same lubrication effect. Adjust the lubricator to 10 drops

per minute at minimum.

As line oilers,

"drip feed" lubricators provide better results than "wick

oilers". Check the silencer for oil trace and adjust the lubricator

for minimal, but not completely without, trace. Too much lubrication

will lead pistons and rollers to clog and should therefore be avoided.

Air Filters

and Pressure Regulators

All air compressors

are equipped with air filters to protect the compressor valves. This

compressed air is clean enough to be used in all of our rotative vibrators.

Small dirt particles will be blown through, but we strongly recommend

the use of an air line filter of 5 micrometers or less. This will help

to prolong the lifetime of the vibrator.

NOTE: For FP-piston

vibrators the use of 5 micrometer filters is strongly recommended due

to the small tolerance between piston and bore.

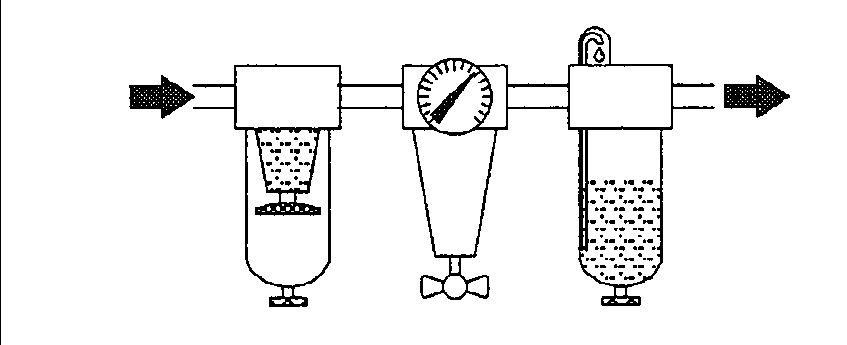

The air filter

must be installed close to the vibrator to avoid rust particles from

iron pipes reaching vibrator. It is advisable to connect the filter,

air pressure regulator and lubricator in line as shown.

|

Correct

installation : filter, then regulator and lubricator.

|

Air Pressure

Pipes

It is of course

possible to adjust the vibrator by decreasing or increasing the air

pressure or the air volume. However the supply and the exhaust-pipes

have to be dimensioned correctly. If the ratio of these tubes is too

small, the vibrator will not be able to run at full power.

The exhaust pipe

should be as short as possible because the volume of the exhausted air

(expanded) is many times greater than the pressure difference.

The respective

formula is V(in) x P(in) = V(out) x P(out) where P is the absolute pressure

and not only the overpressure. Therefore, it can be shown easily that

when running a vibrator at 6 bar (overpressure) the exhaust air volume

is 6 times the air pressure inlet volume.

An exhaust pipe

that is too long or too short will hinder the air movemnt in such a

way that all of the air pressure cannot be transformed in the vibrator

into vibrating energy.

Using the silencer

mounted directly onto the vibrator is the best way to gain as much power

as possible. Since the question of correct pipe diameter is of importance,

the above graph can be used to determine the required value.

| EXAMPLE |

The air consumption

is 900 liters per minute at 4 bar pressure.

The pipe length is 10 meters.

So start at the right side with 900 to the left until 4 bar line.

Now follow 45° up until the break line. Then go straight to

the left until 10 meter line, then 45° up to the right until

the desired line of maximum pressure loss allowed in the system.

The inner diameter and the area can be seen at the left now. |

NOTE: The pressure

loss in the pipe should not be more than 0.5 bar; however, it does not

make sense to minimize this value too much since this will increase

the size and the cost of the pipes required. A value between 0.1 and

0.5 bar will be OK.

The required size

of the exhaust pipes can be determined the same way. Use the vibrator

inlet pressure nomogram lines but instead of inlet pressure use exhaust

pressure that is about 0.2 to 0.5 bar.

Air Valves

and Pressure Regulators

Pressure

regulators

With the help of

a pressure regulator (a needle valve, for example), the vibrator can

be adjusted to its best working conditions. The adjustable flow volume

influences vibration frequency and energy.

We recommend installing

the pressure regulator between air filter and lubricator to get best

results.

Air valves

For some applications

like emptying bins and hoppers it is advisable to use the vibrator intermittently.

To do so you may place a solenoid valve after the lubricator. Do not

put the solenoid valve in line before the regulator and lubricator because

then the regulator has to upstart every time and the air pressure is

not available immediately. This could cause the vibrator to malfunction.

It also is recommended that you place the valve as close as possible

to the vibrator.

NOTE: Do

not place supporting devices such as air filters, pressure regulators,

lubricators, etc. on a vibrating mount. This will cause devices to malfunction.

CAUTION: Make sure the inner width of the valve is large enough. (See Nomogram

to determine diameter and area of air pipes.) Otherwise, the vibrator

will not run at full vibrating energy, and piston vibrators eventually

experience difficulty starting properly.

It is also possible

that piston vibrators will not start when the valve is manually driven

because for a proper start the piston needs to be supplied with full

pressure right from the beginning. When manually driven try to open

the valve as quickly as possible or make use of solenoid valves.